Sustainable Sourcing and Manufacturing Practices

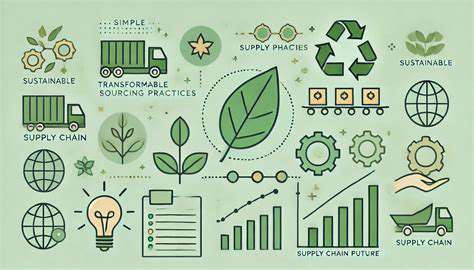

Sustainable Sourcing Practices

Ethical material procurement plays a pivotal role in reducing manufacturing's ecological footprint. Forward-thinking companies now meticulously audit their supply networks, tracing every component back to its origin to address sustainability risks. This rigorous vetting process includes partnering only with vendors who maintain certified environmental protocols and humane working conditions. Selecting partners with verifiable green credentials guarantees product lifecycle accountability while preventing ecosystem damage like forest depletion or water contamination. Organizations serious about sustainability invest heavily in material traceability, validating each resource's extraction and processing history.

Modern sourcing strategies increasingly incorporate repurposed or regenerative materials. This fundamental shift diminishes dependence on finite natural reserves while slashing overall ecological disruption. When manufacturers integrate recycled components, they effectively decrease virgin material requirements, preserving Earth's limited resources and cutting energy expenditure linked to mining and refinement. Additionally, opting for certified sustainable wood or ethically farmed cotton helps maintain biological diversity and bolsters regional economies.

Environmental Impact Assessment

Conducting thorough ecological evaluations represents a non-negotiable phase for conscientious manufacturers. These comprehensive analyses scrutinize production systems from inception to completion, detecting possible contamination points, calculating resource expenditure, and measuring effects on surrounding environments. The resulting data becomes invaluable for crafting reduction tactics and refining operations toward greater ecological harmony.

Grasping the environmental ramifications at every manufacturing stage empowers smarter operational choices. These evaluations frequently uncover hidden ecological concerns that demand creative resolutions. The primary objectives should center on decreasing material waste, limiting emissions, and conserving power across the product's entire existence. Such detailed scrutiny pinpoints chances to enhance sustainability metrics while neutralizing harmful environmental effects.

Manufacturing Processes for Sustainability

Transitioning to eco-conscious production methods stands essential for minimizing industrial environmental damage. This evolution requires adopting breakthrough technologies and innovative approaches to maximize resource efficiency, reduce scrap output, and implement cleaner fabrication techniques. Installing high-efficiency machinery and optimized systems substantially lowers production-related carbon emissions. While these upgrades often necessitate considerable initial capital, they generate impressive financial returns and environmental advantages over time.

Ethical Considerations in Sourcing

Moral principles form the foundation of responsible procurement and production. These considerations expand beyond ecological factors to include equitable employment standards, occupational safety, and societal welfare. Guaranteeing living wages, hazard-free workplaces, and fundamental human rights protections remains imperative for morally sound manufacturing. Corporations must maintain active supplier relationships to ensure these benchmarks are consistently achieved throughout the value chain. This dedication to principled sourcing cultivates consumer trust and enhances brand reputation.

Supply chain visibility and product lineage tracking have become indispensable for ethical operations. Today's buyers increasingly seek detailed information about product origins and creation methods. Offering accessible, transparent supply chain documentation strengthens customer assurance and encourages mindful purchasing decisions. By emphasizing ethical, open business practices, enterprises showcase their devotion to social accountability and help create a more sustainable global marketplace.

Energy Efficiency in Warehousing and Operations

Optimizing Lighting for Energy Savings

Distribution centers typically demand extensive illumination, resulting in massive power usage. Transitioning to eco-friendly lighting alternatives proves vital for sustainable operations. Advanced LED systems, consuming far less electricity than conventional options, deliver remarkable efficiency gains. Intelligent lighting networks that automatically dim based on room occupancy and daylight availability can eliminate unnecessary energy expenditure. A holistic illumination plan incorporating motion-activated fixtures and strategically positioned detectors can revolutionize a facility's energy profile.

Light fixture positioning deserves equal attention to bulb selection. Implementing directed task lighting in specific work zones rather than blanket illumination prevents energy waste by concentrating light where required. Consistent fixture maintenance and cleaning ensures maximum luminosity while preventing efficiency loss from dirt buildup. These incremental upgrades accumulate into substantial long-term reductions, establishing energy-smart lighting as a warehouse sustainability pillar.

Improving HVAC Systems for Reduced Energy Consumption

Climate control installations account for a dominant share of warehouse energy budgets. Installing cutting-edge HVAC equipment featuring variable-frequency motor controls can slash power consumption dramatically. Structural enhancements like proper insulation and thorough weather stripping help contain conditioned air by reducing thermal transfer through walls and ceilings.

Proactive HVAC servicing, including timely filter changes and system inspections, maintains peak efficiency. Introducing programmable thermostats that adapt to occupancy rhythms and automatically regulate temperatures prevents energy waste. Through diligent climate system management, storage facilities can achieve noteworthy reductions in both environmental impact and operational expenses.

Implementing Sustainable Material Handling Practices

Industrial lifting and transport equipment generates significant energy demand. Converting to battery-electric or hybrid alternatives represents a crucial step toward lowering carbon output and enhancing operational efficiency. Streamlining product movement patterns and shortening transfer distances can produce substantial energy savings.

Thoughtful facility design that minimizes material transit lengths yields measurable improvements. Employing optimized loading procedures and integrating autonomous robotic transporters where feasible can boost productivity while cutting energy consumption linked to manual handling. These operational enhancements support more sustainable and energy-aware warehousing.

Waste Reduction and Recycling Initiatives

Minimizing waste production across storage facility activities remains critical for environmental stewardship. Implementing precision inventory controls to prevent overstocking and promoting packaging material reuse can significantly decrease disposal costs and ecological harm. Establishing comprehensive waste sorting and reprocessing systems ensures maximum resource recovery and diversion from landfills.

Fostering an organizational culture prioritizing waste minimization and material cycling helps businesses shrink their ecological footprint while building a greener future. Collaborations with specialized recycling partners and sustainability-focused suppliers can amplify these efforts. Such programs not only enhance energy efficiency but also strengthen brand perception among environmentally conscious consumers.