Enhancing Business Performance Through Strategic Process Optimization

Refining Workflow Procedures

The cornerstone of operational excellence lies in refining workflow procedures. Organizations must conduct thorough evaluations of current methods, pinpoint inefficiencies, and deploy targeted enhancements. Removing redundant steps and introducing automation for routine activities can dramatically cut down on time waste and resource expenditure. These improvements naturally translate to heightened productivity and organizational agility.

Each phase of the operational cycle demands careful scrutiny. Identifying specific pain points and their root causes enables the implementation of precise corrective measures. Consider a procurement process where manual approval routing creates delays - transitioning to digital workflows could produce immediate efficiency gains.

Strategic Resource Management

Optimal performance requires meticulous planning of human capital, materials, and equipment deployment. When resources align perfectly with task requirements, organizations minimize idle time while maximizing productive output. This careful matching ensures operational continuity and prevents resource-related bottlenecks.

Forward-looking resource planning involves predictive analysis of future needs. By anticipating potential shortages or surpluses, businesses can adjust allocations preemptively, maintaining smooth operations even during demand fluctuations.

Intelligent Automation Integration

Modern enterprises increasingly rely on technological solutions to maintain competitive advantage. Automated systems not only accelerate throughput but also enhance precision, eliminating the variability inherent in manual processes. This dual benefit makes automation indispensable for contemporary operations.

From automated inventory tracking to AI-driven customer service platforms, these technologies liberate human talent for more complex, value-added activities. The result is a workforce focused on innovation rather than repetitive tasks.

Evidence-Based Process Optimization

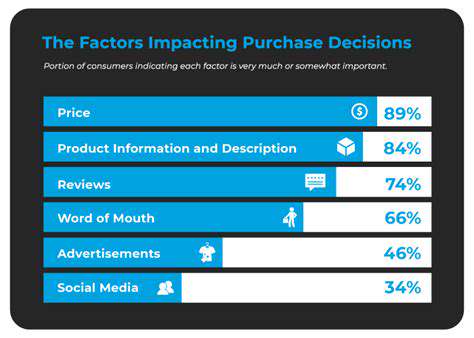

Operational improvements must stem from concrete data rather than assumptions. Comprehensive analytics reveal hidden inefficiencies and validate the effectiveness of implemented changes. This empirical approach ensures that optimization efforts target the areas with highest potential impact.

Key metrics provide the foundation for continuous improvement. Regular review of these indicators allows organizations to track progress, identify regression, and maintain focus on performance priorities.

Fostering Collaborative Excellence

Seamless information exchange forms the backbone of effective teamwork and operational synergy. When communication channels function optimally, teams coordinate efforts effortlessly, preventing misalignment and duplicated work.

Modern collaboration platforms break down organizational silos, creating transparent workflows where responsibilities and progress remain visible to all stakeholders. This transparency accelerates problem resolution and enhances adaptability to changing circumstances.

Continuous Workforce Development

Human capital represents the most dynamic component of operations. Ongoing training initiatives equip employees with evolving skillsets, enabling them to handle increasingly sophisticated processes with greater competence. This investment pays dividends in operational quality and efficiency.

Structured development programs create workforces capable of rapid adaptation to new technologies and methodologies. Such agility proves invaluable in maintaining operational continuity during periods of organizational change or market disruption.

Performance Metrics: Quantifying Operational Success

Strategic Performance Measurement

Effective operations management requires clear benchmarks for success. Performance indicators transform abstract goals into measurable outcomes, providing concrete evidence of progress. Without such metrics, assessing operational effectiveness becomes speculative rather than empirical.

Metric selection must align precisely with organizational objectives. Manufacturing operations might emphasize production yield and equipment uptime, while service organizations may prioritize resolution times and service quality ratings.

Production Performance Analysis

Manufacturing efficiency manifests through several critical indicators. Output consistency, processing durations, and quality incident rates each tell part of the operational story. Elevated defect frequencies might indicate training gaps or equipment calibration issues, while extended cycle times could reveal workflow constraints.

Continuous monitoring of these indicators enables preemptive corrective action before minor issues escalate into major disruptions, ensuring consistent production quality and throughput.

Customer Experience Metrics

Customer loyalty and satisfaction serve as ultimate validators of operational effectiveness. Retention patterns, recommendation likelihood scores, and direct feedback provide windows into the customer perspective. Declining satisfaction metrics often precede revenue impacts, making them valuable early warning indicators.

Proactive response to these signals demonstrates organizational responsiveness and commitment to continuous service improvement.

Financial Health Indicators

Operational efficiency ultimately reflects in financial statements. Revenue trajectories, profit margins, and capital efficiency ratios quantify the monetary impact of operational strategies. These indicators reveal whether process improvements translate into tangible financial benefits.

Regular financial analysis ensures operational decisions align with broader business objectives, maintaining focus on initiatives that drive both efficiency and profitability.

Resource Efficiency Tracking

Sustainable operations require careful monitoring of resource consumption patterns. Energy efficiency metrics, material utilization rates, and workforce productivity measurements highlight opportunities for conservation and optimization.

Detailed resource analysis often uncovers surprising inefficiencies, from excessive energy consumption during non-peak hours to material waste in production processes. Addressing these issues can yield substantial cost reductions while improving environmental sustainability.