The Evolving Landscape of Omnichannel Retail

The Impact of Omnichannel on Inventory Management

Omnichannel retail, with its seamless integration of various sales channels like online stores, physical stores, mobile apps, and social media, significantly alters the traditional inventory management landscape. This shift necessitates a more dynamic and sophisticated approach to tracking, forecasting, and managing stock across all these interconnected points of sale. Traditional methods, often siloed within individual channels, struggle to keep pace with the demands of real-time visibility and responsiveness required by omnichannel shoppers.

Real-Time Visibility and Data Integration

Effective inventory management in an omnichannel environment hinges on real-time visibility across all sales channels. This means that inventory levels in every location – whether a warehouse, a retail store, or an online fulfillment center – need to be constantly updated and accessible to all relevant departments. Integrating data from various systems, including point-of-sale (POS) systems, online order management systems, and warehouse management systems (WMS), is crucial for achieving this level of real-time visibility. This integrated data allows for accurate forecasting and proactive adjustments to inventory levels.

Demand Forecasting and Predictive Analytics

Omnichannel retail necessitates sophisticated demand forecasting models that consider data from multiple touchpoints. Traditional forecasting methods based solely on historical sales data in a single channel are insufficient. Predictive analytics, incorporating data from website traffic, social media trends, and even weather patterns, can provide more accurate predictions of future demand. This allows businesses to proactively adjust inventory levels to meet fluctuating customer needs across different channels.

Inventory Optimization Strategies

Optimizing inventory levels in an omnichannel environment is a complex challenge. Strategies need to consider factors like order fulfillment speed, customer expectations, and the cost of holding inventory. Implementing just-in-time inventory management systems, strategically placing inventory across different fulfillment centers, and leveraging advanced inventory management software are crucial steps in achieving optimal inventory levels. These strategies ensure that the right products are available in the right place at the right time, minimizing storage costs and stockouts.

Multi-Channel Fulfillment and Order Management

Omnichannel retail requires a robust order management system that can handle orders placed through various channels and seamlessly fulfill them. This includes efficient order routing, warehouse management, and shipping procedures. A key component is the ability to fulfill orders from the closest available location, whether it's a local store, a nearby warehouse, or a central fulfillment center. Streamlined order fulfillment ensures fast delivery times, enhancing the customer experience across all touchpoints.

Inventory Management Software and Technology

Modern inventory management software plays a crucial role in supporting omnichannel operations. Advanced inventory management systems are capable of tracking inventory across multiple channels, predicting demand, and optimizing stock levels. These systems often include features for real-time data updates, automated order fulfillment, and inventory forecasting. Choosing the right software that integrates seamlessly with existing systems is paramount for successful omnichannel inventory management.

Customer Relationship Management (CRM) Integration

Integrating inventory management with CRM systems is essential for understanding customer preferences and patterns. This allows retailers to anticipate demand based on past purchasing behavior and tailor inventory strategies accordingly. Real-time inventory data helps avoid stockouts of popular items and promotes targeted promotions and recommendations, ultimately improving customer satisfaction and loyalty across all channels. This integration also supports personalized recommendations and better-targeted marketing efforts.

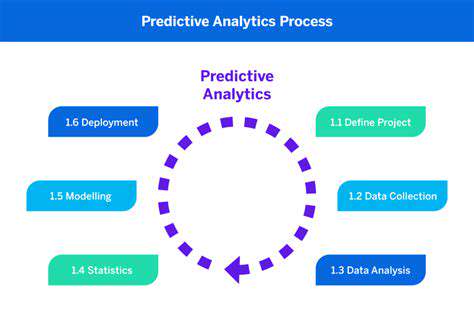

Predictive Analytics for Enhanced Forecasting

Predictive Modeling Techniques

Predictive analytics leverages various statistical and machine learning techniques to forecast future outcomes. These models analyze historical data, identify patterns, and use these insights to predict future trends, behaviors, or events. This process allows businesses to anticipate potential challenges and opportunities, enabling proactive decision-making. The core of predictive modeling lies in building mathematical models that can accurately estimate the probability of different future scenarios based on the input data.

Different modeling techniques are employed depending on the nature of the data and the desired outcome. Regression analysis, for example, is frequently used to predict continuous variables, while classification models are better suited for predicting categorical outcomes. Understanding the nuances of each technique is crucial for selecting the most appropriate model for a given problem.

Data Preparation and Feature Engineering

A critical aspect of predictive analytics is the meticulous preparation of the input data. This involves cleaning, transforming, and preparing the data to ensure its quality and suitability for the chosen modeling technique. Garbage in, garbage out is a fundamental principle in predictive modeling, highlighting the importance of data preparation. This step often includes handling missing values, removing outliers, and converting categorical variables into numerical representations.

Feature engineering plays a vital role in improving model accuracy. It involves creating new features from existing ones, which can sometimes reveal hidden patterns and relationships within the data. These new features can significantly enhance the predictive power of the model.

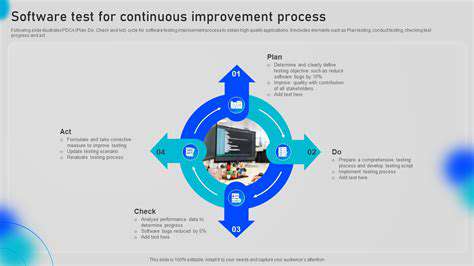

Model Evaluation and Validation

Evaluating the performance of a predictive model is crucial to ensure its reliability and accuracy. Various metrics, such as accuracy, precision, recall, and F1-score, are used to assess the model's ability to correctly predict outcomes. Choosing the appropriate metric depends on the specific application and the relative importance of different types of errors. A comprehensive evaluation process ensures that the model is robust and reliable.

Model validation is essential to prevent overfitting, where the model performs well on the training data but poorly on new, unseen data. Techniques like cross-validation are employed to assess the model's generalization ability and ensure its effectiveness in real-world scenarios.

Deployment and Monitoring

Successfully implementing predictive analytics requires the seamless integration of the model into existing business processes. This involves deploying the model into a production environment and monitoring its performance over time. Regular monitoring is essential to identify any changes in the underlying data patterns that could impact the model's accuracy. Adapting and retraining the model based on the evolving data patterns is a continuous process.

Deployment strategies and infrastructure need to be carefully considered to ensure efficient and reliable model execution. This includes aspects like scalability, maintainability, and security.

Real-World Applications of Predictive Analytics

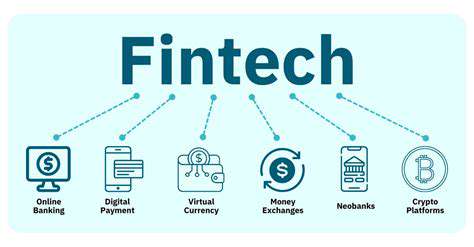

Predictive analytics finds applications across a wide range of industries, from healthcare to finance to retail. In healthcare, it can predict patient readmission rates, enabling proactive interventions and improved patient outcomes. In finance, predictive models are used to assess credit risk and detect fraudulent activities. In retail, predictive analytics can be used to forecast demand, optimize inventory levels, and personalize customer experiences. The applications are diverse and constantly evolving as new technologies and use cases emerge.

These applications underscore the transformative potential of predictive analytics in driving data-driven decision-making and enhancing operational efficiency.

Streamlined Order Fulfillment and Delivery Processes

Optimizing the Order Processing Pipeline

Streamlining the order fulfillment process is crucial for enhancing customer satisfaction and reducing operational costs. A well-defined and automated pipeline ensures orders are processed efficiently and accurately from initial receipt to final delivery. This involves integrating various systems, from the point of sale to inventory management, shipping, and customer communication. Efficient order processing minimizes delays and enhances the customer experience by providing timely updates and accurate tracking information.

By automating repetitive tasks and implementing robust quality checks, businesses can significantly reduce errors and improve the overall order fulfillment accuracy. This automation also frees up valuable personnel to focus on more strategic initiatives.

Inventory Management and Control

Effective inventory management is paramount to maintaining optimal stock levels and avoiding stockouts or overstocking. Real-time inventory tracking systems provide clear visibility into stock levels, enabling proactive adjustments to meet anticipated demand. This ensures that products are readily available to fulfill orders promptly. By accurately predicting demand, businesses can optimize their inventory levels, minimizing storage costs and preventing unnecessary investment in excess stock.

Enhanced Communication and Transparency

Providing customers with clear and consistent communication throughout the order fulfillment process is essential for building trust and maintaining satisfaction. This includes timely order confirmations, shipment updates, and proactive communication regarding potential delays. By providing detailed and transparent information, businesses build customer confidence and mitigate potential anxieties. Clear communication channels, including email, SMS, or dedicated order tracking portals, are vital for this.

Secure and Reliable Shipping Solutions

Selecting reliable and secure shipping partners is critical to ensure timely delivery and minimize potential logistical challenges. Factors such as shipping costs, transit times, and the security of the shipping process should be carefully considered. Partnering with reputable carriers can significantly enhance the customer experience and reduce the risk of lost or damaged packages. Implementing robust tracking systems allows for real-time monitoring of shipments, providing customers with accurate delivery updates.

Customer Relationship Management (CRM) Integration

Integrating order fulfillment with CRM systems allows for a holistic view of the customer journey. This integration provides valuable insights into customer preferences, order history, and feedback. This enables personalized communication and tailored service experiences. By leveraging CRM data, businesses can anticipate customer needs and proactively offer support or address concerns, thereby fostering stronger customer relationships. This data also aids in identifying areas for improvement in the order fulfillment process.

Performance Measurement and Analysis

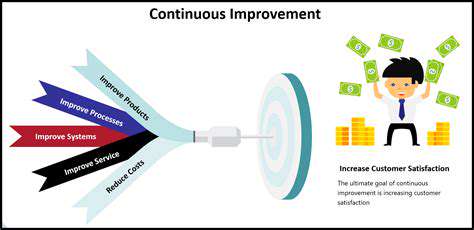

Regularly monitoring and analyzing key performance indicators (KPIs) related to order fulfillment is crucial for identifying areas needing improvement. Metrics such as order processing time, order accuracy, customer satisfaction ratings, and delivery times provide valuable insights. By identifying bottlenecks and inefficiencies in the process, businesses can implement targeted solutions to optimize performance and reduce costs. Data-driven analysis allows for proactive adjustments to the order fulfillment process, ensuring continuous improvement and enhanced efficiency.

Adapting to Changing Customer Preferences and Market Trends

Understanding Evolving Customer Needs

Businesses must continuously analyze and adapt to changing customer preferences to maintain a competitive edge. This involves more than just tracking sales figures; it requires deep dives into customer feedback, online reviews, social media trends, and market research. Understanding the why behind shifts in customer demand is crucial. Are customers seeking greater personalization? Are they prioritizing sustainability and ethical sourcing? Are there emerging trends in product usage or consumption patterns that need to be addressed? By proactively identifying these shifts, businesses can adjust their inventory strategies to meet evolving needs.

Staying ahead of the curve requires a proactive approach to market research. This could involve conducting surveys, analyzing competitor offerings, and leveraging data analytics to identify emerging trends. By understanding the why behind customer choices, businesses can tailor their inventory to align with these preferences, leading to increased customer satisfaction and loyalty. A comprehensive understanding of consumer behavior is essential for inventory management in a dynamic market.

Responding to Shifting Market Trends

Market trends are constantly in flux, influenced by economic factors, technological advancements, and societal shifts. Understanding these trends and their potential impact on demand is critical for effective inventory management. For instance, a burgeoning interest in sustainable products might necessitate a shift in inventory towards eco-friendly materials or suppliers. Similarly, technological advancements can render existing products obsolete or create new opportunities for innovative offerings.

Economic downturns, political instability, and global events can also significantly impact market trends and consumer behavior. Adapting inventory strategies to account for such fluctuations is crucial for maintaining profitability and resilience. Accurate forecasting models, coupled with flexible inventory management systems, become essential tools for navigating these unpredictable shifts. By incorporating a multitude of data points and forecasting methodologies, businesses can more effectively predict and respond to changing market conditions.

In addition to the above, recognizing seasonal variations in demand is also vital. Understanding historical sales data and identifying patterns in seasonal fluctuations can enable businesses to adjust their inventory levels accordingly. This proactive approach minimizes the risk of stockouts during peak demand periods and reduces holding costs during off-seasons. A well-tuned inventory strategy can balance the need for responsiveness to market trends with the need for efficient resource allocation.

The ability to quickly adapt to changing market conditions is paramount in today's dynamic business environment. Businesses that anticipate and respond to these fluctuations are better positioned to thrive and maintain a competitive advantage. This requires a commitment to continuous monitoring, analysis, and adaptation in inventory management strategies.

Ultimately, successful inventory management in the face of market shifts hinges on agility, responsiveness, and a commitment to staying informed about the ever-evolving landscape.