Predictive Analytics for Proactive Inventory Management

Optimizing Inventory Levels

Predictive analytics plays a crucial role in optimizing inventory levels by forecasting future demand. By analyzing historical sales data, seasonal trends, and external factors like promotions and economic indicators, businesses can anticipate future demand fluctuations. This allows them to adjust inventory levels proactively, reducing the risk of stockouts or excess inventory. Accurate forecasting minimizes holding costs and ensures that products are available when customers need them, leading to increased customer satisfaction and reduced operational expenses.

Understanding the variability in demand is key. Predictive models can identify patterns and anomalies in sales data, allowing businesses to anticipate potential spikes or dips in demand. This proactive approach allows for adjustments in inventory levels, avoiding costly stockouts during peak periods and preventing the accumulation of excess inventory during slow periods.

Forecasting Demand with Accuracy

Accurate demand forecasting is the cornerstone of effective proactive inventory management. Predictive analytics algorithms leverage sophisticated statistical methods and machine learning techniques to analyze various data points, including historical sales data, market trends, and external factors like weather patterns or economic conditions. This analysis helps identify potential future demand fluctuations, allowing businesses to adjust their inventory levels accordingly. The more accurate the forecast, the more effective the inventory management strategy.

Improving Supply Chain Visibility

Predictive analytics enhances supply chain visibility by identifying potential disruptions and bottlenecks. Analyzing data from various sources, such as suppliers, transportation networks, and manufacturing processes, allows businesses to anticipate potential delays or disruptions. This proactive approach enables them to take corrective actions to mitigate these risks, ensuring timely delivery of products to customers and maintaining smooth operations.

Real-time Inventory Monitoring

Real-time inventory monitoring is a critical element of proactive inventory management. Predictive analytics tools can provide real-time insights into inventory levels, allowing businesses to quickly respond to changes in demand or supply. By monitoring inventory levels and sales data in real-time, businesses can identify potential stockouts or overstocking issues before they impact customer orders or financial performance. This agility is crucial in today's fast-paced omnichannel environment.

Proactive Risk Management

Predictive analytics provides a powerful tool for proactive risk management in inventory management. By identifying potential risks such as supply chain disruptions, changes in customer demand, or unexpected market fluctuations, businesses can anticipate and mitigate these risks. This proactive approach allows businesses to avoid costly issues like stockouts, overstocking, and lost sales opportunities. Risk mitigation is essential for maintaining profitability and ensuring business continuity.

Enhanced Customer Satisfaction

By effectively managing inventory levels and anticipating demand, predictive analytics contributes to enhancing customer satisfaction. Proactive management ensures that products are available when customers need them, minimizing stockouts and order fulfillment delays. This leads to happier customers, increased repeat business, and a stronger brand reputation. The ability to meet customer demand consistently is paramount in today's competitive market.

Cost Reduction and Increased Profitability

Finally, predictive analytics for inventory management leads to significant cost reduction and increased profitability. By optimizing inventory levels, businesses can reduce holding costs associated with storage, insurance, and potential spoilage. Reduced stockouts minimize lost sales and improve operational efficiency. The overall result is a more streamlined and profitable inventory management system, which is essential for success in the omnichannel environment. These cost savings can be reinvested in other areas of the business, leading to further growth and development.

Optimizing Fulfillment Strategies for Seamless Omnichannel Experiences

Understanding the Omnichannel Landscape

Omnichannel fulfillment isn't just about having a website and a physical store; it's about creating a cohesive customer journey across all touchpoints. This means understanding how customers interact with your brand, from browsing your online store to picking up an order in-store. A seamless omnichannel experience hinges on real-time inventory visibility, consistent order management, and personalized communication strategies across platforms. This requires a deep dive into customer behavior and preferences to tailor the fulfillment process to their needs.

Effective omnichannel fulfillment necessitates a robust technological infrastructure capable of handling diverse order types and channels. This includes integrating various systems, from your e-commerce platform to your inventory management system and point-of-sale (POS) systems. Successful integration eliminates friction points and ensures accuracy in order processing and delivery, leading to a positive customer experience. Furthermore, accurate order tracking and real-time updates across all channels are crucial for keeping customers informed and satisfied.

Streamlining Order Processing and Delivery

Optimizing order processing and delivery is paramount to a smooth omnichannel experience. This involves implementing efficient workflows that handle orders placed through various channels – online, mobile apps, phone calls, or in-store – with equal speed and accuracy. Efficient inventory management systems are essential to ensure that orders can be fulfilled quickly and without delays. This includes strategies for predicting demand, managing stock levels, and ensuring that products are readily available for fulfillment across all channels.

Integrating various delivery options, such as shipping, in-store pickup, and curbside pickup, offers customers flexibility and choice. This empowers customers to select the method that best suits their needs and preferences. Providing real-time order tracking updates, regardless of the chosen fulfillment method, keeps customers engaged and informed throughout the entire process. This transparency builds trust and strengthens the customer relationship.

Personalizing the Customer Journey

Personalization is key to creating a truly exceptional omnichannel experience. By leveraging data from various touchpoints, businesses can tailor the fulfillment process to individual customer needs and preferences. This might involve offering personalized recommendations, suggesting alternative delivery options, or providing customized order tracking updates. This level of individualized attention enhances customer satisfaction and fosters brand loyalty.

Implementing customer relationship management (CRM) systems can aid in collecting and analyzing customer data to personalize the fulfillment experience. This data can be used to anticipate customer needs and tailor communication strategies, such as sending personalized shipping notifications or offering exclusive deals based on past purchases. By proactively addressing customer needs, businesses can enhance the overall omnichannel fulfillment experience.

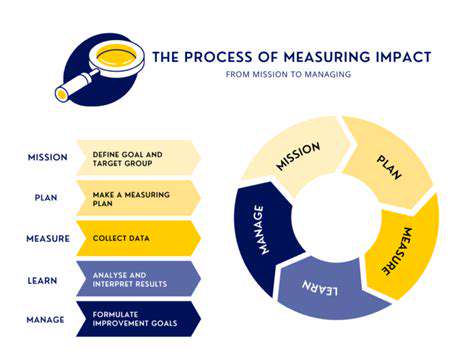

Measuring and Adapting Fulfillment Strategies

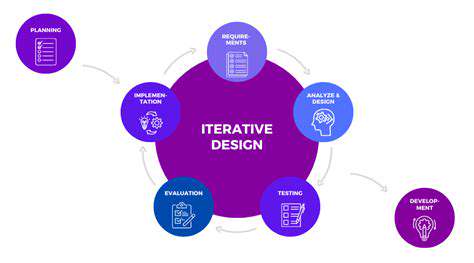

Continuous monitoring and analysis of fulfillment performance are crucial for optimizing omnichannel strategies. Tracking key metrics such as order fulfillment time, order accuracy, and customer satisfaction levels provides insights into areas needing improvement. Analyzing customer feedback through surveys, reviews, and social media interactions helps identify pain points and opportunities for enhancement. This data-driven approach allows businesses to adapt and refine their strategies, ensuring that the omnichannel experience remains seamless and meets evolving customer expectations.

Implementing data analytics tools allows for a deeper understanding of customer behavior and preferences, enabling businesses to proactively identify trends and adjust their strategies accordingly. This iterative approach to optimization ensures that fulfillment processes stay aligned with customer needs and expectations, continuously improving the omnichannel experience. Regular performance reviews and adjustments based on the insights gained are essential to long-term success in the omnichannel landscape.

Inventory Management Technology: A Powerful Tool

Real-time Visibility and Control

Effective omnichannel inventory management hinges on real-time visibility across all sales channels. Modern inventory management technology provides dashboards and reporting tools that track stock levels in real-time, regardless of whether an item is held in a warehouse, a retail store, or available for immediate delivery from a fulfillment center. This constant, up-to-the-second view allows businesses to quickly react to fluctuations in demand, optimize stock levels, and prevent costly stockouts or overstocking.

Accurate inventory data is crucial for maintaining optimal stock levels across multiple channels. Real-time tracking eliminates guesswork and enables businesses to make data-driven decisions about inventory allocation, ensuring products are available where and when customers expect them, leading to improved customer satisfaction and reduced operational costs.

Improved Forecasting and Planning

Sophisticated inventory management systems go beyond simply tracking current stock levels; they offer powerful forecasting capabilities. By analyzing historical sales data, seasonal trends, and external factors, these systems can predict future demand with greater accuracy. This allows businesses to proactively adjust inventory levels, preventing stockouts and minimizing storage costs.

Accurate forecasting also enables better planning for procurement and production. Knowing future demand allows businesses to place orders with suppliers at the optimal time, ensuring a consistent supply of goods without tying up excessive capital in inventory. This streamlined process significantly reduces waste and improves operational efficiency.

Optimized Order Fulfillment

Omnichannel inventory management technology streamlines the order fulfillment process across all sales channels. By integrating with various platforms, including e-commerce sites, mobile apps, and physical stores, the system ensures that orders are processed quickly and accurately. This includes automatically updating inventory levels as orders are placed and fulfilled, and routing orders to the most appropriate fulfillment center.

This automated process minimizes errors, reduces order processing time, and enhances customer satisfaction by ensuring orders are delivered on time, every time. This improved efficiency leads to increased customer loyalty and positive brand perception.

Enhanced Customer Experience

Robust inventory management systems play a critical role in enhancing the overall customer experience. By ensuring products are available when and where customers want them, businesses can fulfill orders seamlessly and avoid frustrating delays. This is especially crucial in an omnichannel environment where customers expect instant access to products across various platforms.

Real-time inventory visibility also enables businesses to proactively address customer inquiries about product availability. Accurate and up-to-date information about stock levels builds trust and confidence in the brand, leading to improved customer satisfaction and loyalty. This positive customer experience is essential for sustained business growth and success.

Integration and Automation

Modern inventory management technology facilitates seamless integration with other crucial business systems, such as accounting software, CRM systems, and e-commerce platforms. This integration streamlines workflows, automates tasks, and eliminates redundant data entry. By connecting different systems, businesses can gain a holistic view of their operations.

Automation of various processes, such as order fulfillment and inventory updates, further improves efficiency and reduces manual errors. Automated processes free up valuable time and resources, allowing employees to focus on more strategic tasks, ultimately boosting overall productivity and profitability. This seamless integration and automation are critical for maintaining agility and responsiveness in today's fast-paced business environment.