Bridging the Gap Between Channels with a Single Source of Truth

Centralized Data for Accurate Inventory Tracking

Imagine a world where inventory data flows seamlessly, free from the chaos of conflicting spreadsheets and outdated reports. A single source of truth acts as the backbone for accurate inventory management, creating harmony across all departments. When sales teams and fulfillment centers operate from the same playbook, costly mistakes vanish and productivity soars. Picture warehouse managers glancing at real-time dashboards to make snap decisions about stock replenishment - this isn't futuristic fantasy, but today's operational reality.

Improved Sales Forecasting and Order Fulfillment

The magic of unified inventory systems lies in their predictive power. Like meteorologists tracking storm patterns, these systems analyze sales history, current stock positions, and market pulses to forecast demand with uncanny accuracy. One retailer slashed their overstock by 37% simply by letting their inventory system guide purchasing decisions. The ripple effects? Happier customers receiving orders faster, and finance teams smiling at healthier bottom lines.

Enhanced Customer Experience

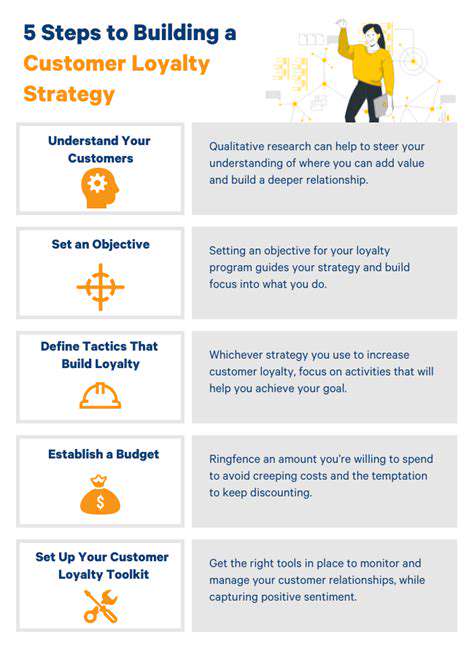

Nothing frustrates shoppers more than discovering their in stock item vanished during checkout. Unified inventory data erases these digital letdowns. When e-commerce platforms display accurate stock counts that sync with physical shelves, customer trust grows exponentially. Consider the luxury brand that reduced customer complaints by 62% after implementing real-time inventory visibility - proof that transparency drives loyalty.

Streamlined Supply Chain Management

Supply chains resemble delicate ecosystems where one delay can trigger cascading problems. A centralized inventory system acts like an air traffic control tower, spotting turbulence before it disrupts operations. One electronics manufacturer averted $2.3 million in potential losses by using their system to reroute components during a port strike. This level of visibility transforms supply chains from reactive to proactive operations.

Reduced Operational Costs

The financial wastage from manual inventory processes would shock most executives. Studies show companies waste up to 20% of their operational budget on preventable inventory errors. Automated inventory tracking eliminates this bleed, like a financial tourniquet staunching unnecessary expenses. One distributor reclaimed 15,000 labor hours annually by ditching their error-prone spreadsheet system.

Improved Data-Driven Decision Making

Inventory data tells compelling business stories for those who listen. Patterns emerge showing which products fly off shelves and which gather dust, guiding smarter purchasing strategies. A sporting goods chain discovered their best-selling camping gear wasn't what they expected - intelligence that reshaped their entire product lineup and boosted margins by 8%.

Increased Inventory Accuracy and Reduced Losses

Theft, damage, and misplacement plague traditional inventory systems. Retailers lose nearly $50 billion annually to inventory shrinkage - a hemorrhage that unified systems can dramatically reduce. One pharmacy chain cut their shrinkage rate in half within six months of implementation, proving that accurate tracking pays for itself quickly.

Optimizing Stock Levels Across All Channels

Optimizing Inventory Management

Inventory mastery separates thriving retailers from struggling ones. The sweet spot between empty shelves and overstuffed warehouses represents millions in potential profit. Like Goldilocks seeking the perfect porridge, businesses must balance availability against carrying costs - a challenge that grows more complex with each additional sales channel.

Forecasting Demand

Demand forecasting resembles weather prediction - both blend science with intuition. Advanced algorithms now digest everything from social media trends to weather patterns to predict sales surges. When a Midwest hardware chain noticed their snowblower sales spiked two days before major storms, they adjusted staffing and inventory accordingly - turning weather forecasts into profit forecasts.

Supply Chain Visibility

Modern supply chains stretch across continents, making visibility crucial. One apparel company averted disaster by spotting a fabric delay in Vietnam and airfreighting alternatives before production stalled. This supply chain transparency transforms inventory management from guessing game to strategic advantage.

Implementing Inventory Control Systems

Barcode scanners and RFID tags have revolutionized stock tracking. A grocery chain reduced inventory discrepancies by 90% after implementing mobile scanning - proving technology beats clipboard audits every time. These systems don't just count products; they create accountability throughout the organization.

Analyzing Sales Data

Sales reports contain hidden insights waiting to be uncovered. When a bookstore chain noticed crime novels sold better near universities, they reshaped their merchandising strategy. Such discoveries highlight how data analysis turns inventory from cost center to profit driver.

Setting Safety Stock Levels

Safety stock represents the business equivalent of a spare tire. Too little leaves you stranded; too much weighs down performance. A medical supplier perfected their safety stock formula after analyzing years of emergency orders - now they maintain just enough extra inventory without crippling cash flow.

Utilizing Technology for Optimization

AI-powered inventory tools act like crystal balls for stock management. One retailer's system predicted a toy craze months before it trended, allowing strategic stockpiling that generated $4.2 million in extra revenue. This predictive power makes technology the ultimate inventory optimization partner.

Driving Efficiency and Profitability in Omnichannel Retail

Optimizing Operational Processes

Process bottlenecks strangle retail efficiency like kinks in a garden hose. A department store eliminated 37 process steps from their returns procedure, cutting handling time by 65%. Such optimizations demonstrate how scrutinizing workflows uncovers surprising inefficiencies. Digital workflow tools illuminate these opportunities, acting like X-rays for business processes.

Leveraging Technology for Automation

Automation handles the mundane so employees can focus on the meaningful. When a cosmetics chain automated their inventory replenishment, store managers gained 11 hours weekly for customer engagement. This reallocation of human capital from administrative tasks to revenue-generating activities represents automation's true value.

Improving Supply Chain Management

Agile supply chains resemble championship sports teams - responsive, coordinated, and resilient. A furniture manufacturer slashed lead times by 40% through supplier collaboration portals, proving communication drives velocity. In today's retail environment, supply chain prowess often determines market winners from also-rans.

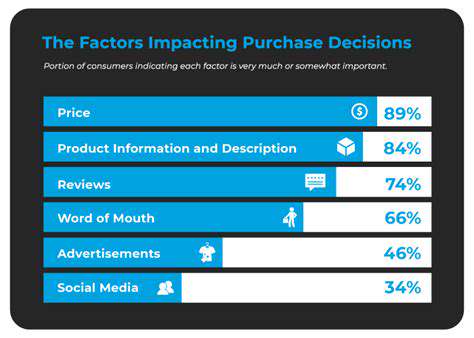

Enhancing Customer Relations

Customer service excellence creates economic moats around businesses. A pet supply retailer's AI-powered recommendation engine boosted average order value by 22% while making shoppers feel understood. This marriage of technology and personalization represents retail's future.

Enhancing Employee Engagement

Motivated employees generate disproportionate value. A fashion chain's gamified training program increased sales per employee by 18%, showing that investment in people pays dividends. In the experience economy, engaged staff create the memorable interactions that build brand loyalty.

Financial Planning and Control

Financial discipline separates enduring retailers from flash-in-the-pan operations. One specialty foods chain avoided bankruptcy by implementing rolling 13-week cash flow forecasts during a market downturn. This financial vigilance ensures companies survive rough patches to thrive during recoveries.